Since the introduction of the Light Emitting Diode or LED in to grow technology, there has been arguments and aversion to the modern alternative.

At first, LEDs seemed to fail to accurately pinpoint and perform the in necessary section of the light spectrum. Not only did they seemingly fail to perform, but also came at a much greater upfront cost. HPS systems were much more reliable, being tried and tested for years in the agricultural industry.

This is another reason that growers and horticultural professionals are opposed to LED, as many live by the mantra of “If it ain’t broke, don’t fix it.” However, issues began to arise when LEDs became more engineered towards horticulture.

As time progressed and technology was further perfected, LEDs caught up to the performance of their HPS/MH counterparts.

Now, in 2018, we here at Illumenedge wanted to take another look.

In this post, we will conclusively compare the specific benefits and detriments to each grow light technology.*

I will go over the following areas in detail and highlight

where each respective technology excels and fails:

* This is a general view of HPS vs LED. Each grow room, tent, or facility requires different components and specifications. This review is based primarily on the general differences in purchasing and implementing a grow operation.

- Yield

- Energy

- Heat

- Area & Spacing

- Photosynthetic Photo Flux (PPF) & Density (PPFD)

- Upfront Costs

- Lifetime

- Safety

- Honourable Mentions & Conclusion

CASE STUDY: DELVIRO GROW

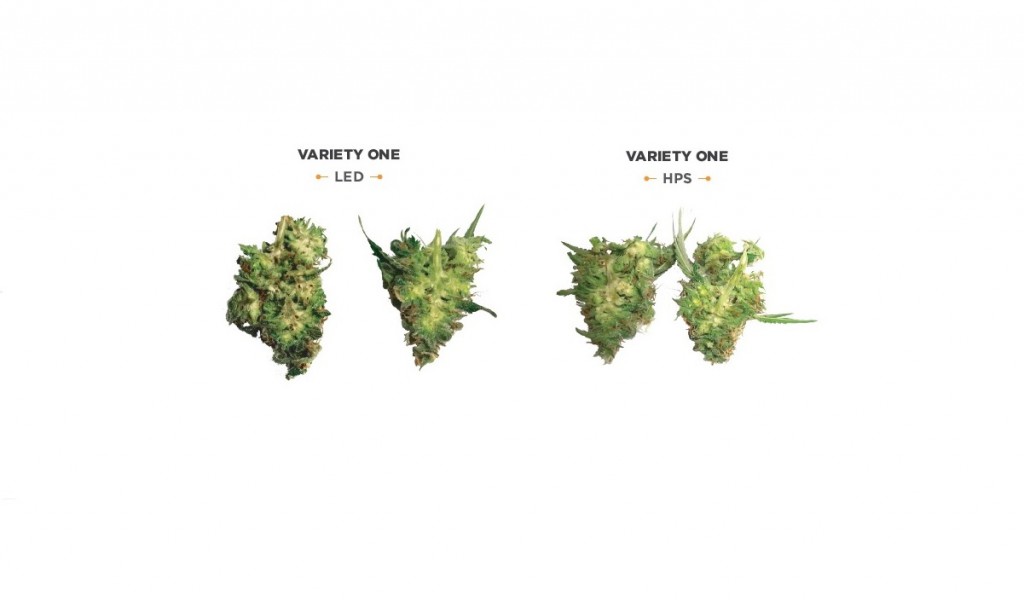

Here is a photo of a study conducted by DelviroGrow.

In this study, they compared ten 1000W HPS vs ten 600W LED fixtures ability to grow and effectively produce cannabis.

In Variety 1 of the case study, 8 plants were utilized to conduct the comparison.

The HPS plants had a yellow-y tinge and produced a total of 14.10lbs of wet cannabis (equivalent to approximately 9.85lbs dried)

The LED plants had a much healthier dark green colour, as well as resulting in a total yield of 17.65lbs wet (12.4lbs dried).

There are many advantages to growing cannabis under LEDs, including safety, yield, cost, and maintenance.

Trusted HPS manufacturers like EYE Hortiilux continue to produce new HPS & Metal Halide fixtures, like the CMH315, pictured above. Their bulbs are the horticulture industry standard.

i. YIELD

………..Arguably the most controversial topic (aside from iv. Quality), yield seems to be a factor that depends primarily on the grower’s abilities and knowledge rather than the type of light the plants are receiving. The HPS industry minimum would be approximately .5 or half a gram per watt used. That means one 1000W HPS fixture would produce a total of 500g per harvest, or just over a pound.

……….From outside sources, many claim that LED technology can produce up to or more than 1.0g/watt. In the study conducted by Delviro, we saw the LED technology growing cannabis at 1.55lbs/plant (dried). That would be about 695 grams of cannabis, averaging out at an impressive 1.16g/watt. The fact of the matter is that yield per watt is the most important aspect for many growers and many retailers. This is the main reason why I have covered it here first.

……….Although yield is not the only important factor, it is the initial identifying catalyst that will determine whether or not LED technology is a suitable adversary to traditional HPS solutions. A two-year academic study presented at the Cannabinoid Conference in Cologne, Germany, in September 2017 entitled The Effect of Light Spectrum on Cannabis Sativa Morphology and Cannabinoid Content’ showed that not only were yields slightly higher, but the LED fixtures produced more internodes on plants. LEDs also produced better compound accumulation and compact growth habit, meaning higher levels of THC and CBD in each plant and more clusters of bud. In the conclusion of their study, the LED produced cannabis had THC levels 26% to 38% higher than the HPS product.

ii. Energy

……….Here is where LED and HPS lights seem to differ the most. The massive 400W difference between a standard HPS set-up and modern LED is not the only area where one will find a reduction in energy usage. Although the 40% savings of light-energy output is definitely remarkable, it is clear that there are more areas where savings can be found in such aspects like ballasts, exhaust fans, temperature and humidity controls, HVAC, and maintenance.

……….Many growers find that, following the switch to LED, their AC usage is reduced by approximately 75%. One of these units can be the biggest energy-guzzler in your entire operation, so this switch is critical to your energy bill. You reduce your operations overall energy usage as ventilation and exhaust fans are rendered obsolete and maintenance is drastically reduced.

Compare for example a 10-plant grow operation for HPS; you would need at least 3 fixtures (3,000 watts), an exhaust system for each, an AC unit of at least 10,000BTU, and temperature, humidity, and Co2 controls. This could rack up to upwards of 7,000 watts!

……….In comparison, an LED system would still require HVAC and environment controls, however, the usage of these systems are reduced heavily. There is far more math I could get in to here but each grow operation is so specific that even an anecdotal example would not be of much use.

iii. Heat

……….Whether you’re dealing with 1, 10, 50, or 100+ HPS lamps, you’re going to see a massive influx of heat in to your environment. The heat produced by a 250W HPS lamp is so great even that needs ventilation. These fixtures typically don’t have any solution built in for the ample heat provided so you must work around this. That means catering your environment to HPS with fan-powered exhausts for each light, large AC units that run while and after your lights are on. This can cause even more issues if your area is not equipped or suitable for growing.

……….The reason HPS lamps generate so much heat is because the light is created by the ignition of gas within the lamp. LED fixtures utilize very thin layers of semiconductor material. These materials either have an excess or a deficient amount. This disparity between layers causes electrons to move therein generating light. The heat per watt is far greater with an HPS fixture compared to LED. This technology is far more efficient in transferring energy in to light, as it produces less heat and has a higher wattage equivalency to HPS (600w vs 1000w).

……….Another key aspect for many LED fixtures is that they use the metal frame as a heat-sink, further decreasing and dissipating any heat output.

iv. Area & Spacing

……….Every grower knows that your environment is one of your most crucially important factors that must be perfect. When you remove your hot HPS fixture, you will immediately make your environment more stable and far easier to maintain. Your area will be less humid and will rest at a more stable temperature. You’re also able to remove many additional physical components with the traditional HPS system after introducing LED fixtures, such as fans, environment control systems, and larger AC units.

……….A large benefit with LEDs is that you reduce the required vertical space for growing, as these lights can be fixated far closer to the plants compared to HPS. Another major benefit to the spacing of LED fixtures is that some are panel-style, like the FutureGreen HiiPower 600W. This allows the grower to align them in an ideal fashion, dispersing good PAR throughout the entire canopy. The change to 600W can also allow you to increase your number of fixtures if you are limited in your electrical footprint.

v. Photosynthetic Photo Flux (PPF) & Density (PPFD)

……….With many LED fixtures, more light is emitted because the source is larger and more dense, therefore we’re getting better canopy penetration. LED grow lights also typically have better PAR and higher PPF & PPFD levels, ranging from 700-1000.From most lights, you’ll want at least 2.0 μmol/s. For example, the FutureGreen HiiPower 600W White LED has an average PPFD of 750 at 20″ and a peak of over 1000 μmol/m2/s.

Another advantage of LED is that these lights generally have higher levels of PAR deeper into the canopy because of the dynamic light source. It is a wider and longer fixture, also allowing you to be able to grow a larger number of denser, stronger plants.

Because of the nature of how an HPS lamp is limited in size and light distribution, it creates hot-spots on plants as well as on the photosynthetic photon flux density map. This means it’s PPFD is generally very high in the center of the ray but deteriorates as it expands outwards towards the ends of the area. This does not occur with LEDs as diodes are clustered and placed specifically to space the PPFD accurately from all points of the fixture. Another issue seen is that the strong yellow light emitted from HPS fixtures does little to fuel photosynthesis.

vi. Upfront Costs

……….Here is the only category where LED could be considered the “loser”.

………………..In fact, it’s clear that within the last few years LED grow technology’s immense upfront cost has decreased as competition increased, engineering furthered, and users have become more familiar with the change. Although this cost has certainly decreased, it’s clear that LED start up cost is significantly higher than HPS.

……….An HPS fixture, bulb, and ballast has a lower start-up cost compared to the standard Full Spectrum LED fixture. All major grow rooms, greenhouses, and facilities need HVAC regardless of whether HPS or LED is used. The difference is in the size and usage of these auxiliary components. Upfront there is an investment, but these fixtures are going to last you a minimum of ten years versus having to buy two new bulbs for every fixture once a year.

……….When considering your lighting solution, remember that with LED, you’ll save on essentially the rest of your entire lighting system.

vii. Lifetime

………………………………….Quick Maths!:

………………..You buy an LED fixture and look at your warranty. It is 100,000 hours, the industry standard. Although your fixture was a lot more expensive up front compared to an HPS setup, here is why it is worth it.

……….HPS lamps must be changed every 2-3 cycles (6-9 months) because they lose efficiency and PPF. A standard 3 month grow cycle requires 16 hours of light a day for the first month in the vegetation stage (480 hours) and 12 hours of light a day for the second and third month in the flowering stage (720 hours). That means you’re getting approximately 2,400-3,600 hours out of your standard HPS bulb.

So, in the end, the number you are paying per hour for your fixtures are:

LED: .015¢ per hour HPS: .83¢ per hour

That means you’re paying more than 55x * less per hour for your LED fixture versus your HPS.

*note: The numbers are based on a $1,500 LED fixture over a 100,000 hour warranty and a $200 HPS industry standard bulb over a two standard 3-month cannabis grow cycles.

The fact is clear that HPS last 2-3 cycles while LED lamps would last approximately 83 cycles or for about 30-40 times more.

viii. Safety

……….Last but certainly not least, but usually the most underrated. Safety for your operation and your own well being are increased drastically removal of HPS systems eases upkeep and relaxes your environment overall.

……….Firstly, as covered previously in this post, the heat from a 1000W HPS lamp is incredibly high and requires ventilation. Not only is this a fire hazard for your room, tent, plants, or otherwise but it is also a burn risk for you as you move through your facility or replace your bulb. Even after waiting for what seems like long enough for the bulb to cool, it can remain extremely hot. An LED, plainly said, will not burn you or start a fire if it falls or is damaged. Replacing these bulbs is also a fall hazard for many growers and operations managers as some facilities are not equipped as extensively as others.

……

ix. Honourable Mentions & Conclusion

Throwing out old lamps: You can be proud you are supporting a far more energy efficient solution with LEDs as well as one with no waste production.

Cost Confusion: Although you may be paying more for an LED fixture or setup, you’ll see the return of investment within the first two years. Many growers idolize the ‘low cost’ of an HPS fixture and lamp but they disregard so many other costly factors.

Trial and Error: Many growers are willing to make the change, increasingly so as technology advances and fellow industry peers change their styles and systems.

In conclusion, LEDs are better in essentially all categories so, if you are willing to put down the money at the start, you’ll see your lights start to pay for themselves. They are safer, more engineering, far more modern, and bring practically no maintenance after initial install. Much research on the topic of LED vs HPS is biased as it’s conducted and reported on by LED grow light companies, however, there is accurate empirical evidence. This evidence leans heavily in favour of LED grow light technology which is enough to convince us.

Sources:

http://www.hortidaily.com/article/39002/Academic-research-into-HPS-vs.-LED-for-cannabis-cultivation

http://plantozoid.com/led-grow-light-vs-hps/

http://www.growweedeasy.com/5-reasons-why-hps-lights-still-dominate

https://www.progrowtech.com/2017/11/choose-led-hps-lighting-cannabis-harvests/

https://www.htgsupply.com/informationcenter/resources/led-vs-hps-which-grow-lights-are-better

https://growlightcentral.com/blogs/news/led-vs-hps-grow-lights